Guest post by John Hunter, founder of CuriousCat.com.

Deming’s management ideas are not prescriptive. The principles are useful to organize your thinking and adapt concepts to your situation. That provides a great deal of flexibility to changing conditions. And those principles result in creating a management system that is robust in the face of changing conditions.

COVID-19 has resulted in rapidly changing conditions that are very challenging for businesses to adapt to. This post provides links to several articles discussing how to use Deming’s management principles to aid in adapting to the economic and business conditions imposed upon us in the last year.

Lean the Virus – Applying Lean principles to the COVID-19 response

This paper describes how lean concepts and techniques can be applied to the pandemic

response. It explains how the principles of quality, efficiency, and standard work apply to

elements of the response including regulation, supply chain management and data collection. The

paper urges the integration of lean principles and techniques into public management systems

during this public health crisis and going forward.

This paper looks at the large systems and how important it is to apply the lean thinking and Deming’s ideas to our responses at the public health level.

What the Quality Improvement Community Brings to the Table During a Pandemic

During a pandemic, it can be helpful to use framing devices to help organizations think through decisions and determine what solutions or improvements are needed.

“It is just getting your mind together,” noted Donald Berwick, MD, MPP, FRCP, president emeritus and senior fellow at IHI. “When you are fearful and when there is uncertainty around, frameworks help.”

For example, Berwick noted one of the core frameworks used in the QI community is the System of Profound Knowledge, developed by the noted engineer, W. Edwards Deming. Within this framework, there are four categories of knowledge:

knowledge of systems;

knowledge of variation;

knowledge of psychology;

knowledge of how to learn.

Application of the PDCA cycle for standardized nursing management in a COVID-19 intensive care unit

the nursing management team adopted the PDCA cycle to identify the problems, propose reasonable and effective suggestions, and implement continuous improvement, so as to ensure the quality and effectiveness of the nursing care.

Nine countermeasures were proposed and implemented accordingly. After 2 weeks of implementation and improvement, the existing problems were effectively addressed and the management of the ICU was gradually standardized, which ensured effective nursing care in the ICU.

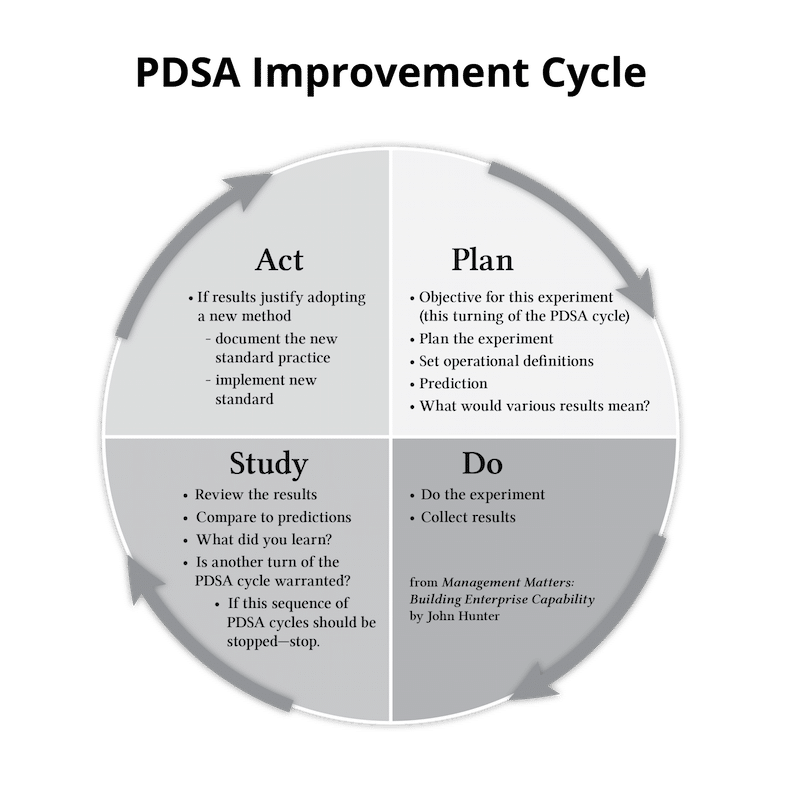

While the write-up does list concrete improvements, the explanation of the Plan-Do-Study-Act (PDSA) process could easily confuse people. I often see confusion over what the PDSA process actually entails. Our resources page, Deming on Management: PDSA cycle, provides resources on how to effectively apply the PDSA improvement cycle. I am fond of the image included here from my book; that image shows that “do” is “doing the experiment” which in my experience is often a part of the process that confuses those trying to apply PDSA.

Analyzing the Implications of COVID-19 on Supply Chain Quality Management

This paper looks at supply chain management, which is one of the aspects of Toyota’s Just in Time (JIT) manufacturing that is often missed. There are numerous reasons for JIT: making problems visible, reducing waste, reducing inventory costs, allowing quick adjustments to market conditions. Many cost-focused organizations fail to understand what, it seems to me, is the most important reason for JIT, which is to make problems visible. JIT is not meant to focus on reducing costs. It is meant to focus on improving the overall system (and reducing costs is beneficial to that aim). But an understanding of the risks of such a system are critical and must be addressed by the overall management system.

Toyota has locked in many months’ supply of microchips because they looked at the overall system and saw the risks of microchip supply scarcity as too big a risk and therefore adjusted their systems (which include their suppliers) to include a large buffer for microchips. How Toyota thrives when the chips are down

After the catastrophe severed Toyota’s supply chains on March 11, 2011, the world’s biggest automaker realised the lead-time for semiconductors was way too long to cope with devastating shocks such as natural disasters.

That’s why Toyota came up with a business continuity plan that required suppliers to stockpile anywhere from two to six months’ worth of chips for the Japanese carmaker, depending on the time it takes from order to delivery.

Toyota learns from results and maintains that knowledge for decades. Often organizations adapt in the short term and, over time, lapse back into the same systemic weaknesses that caused them problems. So a few years later, they fail in a way that would have been prevented if they just learned and kept the improvements from that hard-learned lesson in place.

More articles: Continuous Improvement in Schools in the COVID-19 Context, Page1/31Application of PDCA Cycle Management forPostgraduate Medical Students During the COVID-19 Pandemic

Covid19 related posts on our blog: How Can Deming’s Management Ideas Help During the COVID-19 Pandemic? – Deming Company was Ahead of COVID-19 – India Fights COVID-19 with Control Charts – Systemically Non-Systemic: COVID-19 through the Deming Lens