Guest post by John Hunter, author of Management Matters: Building Enterprise Capability.

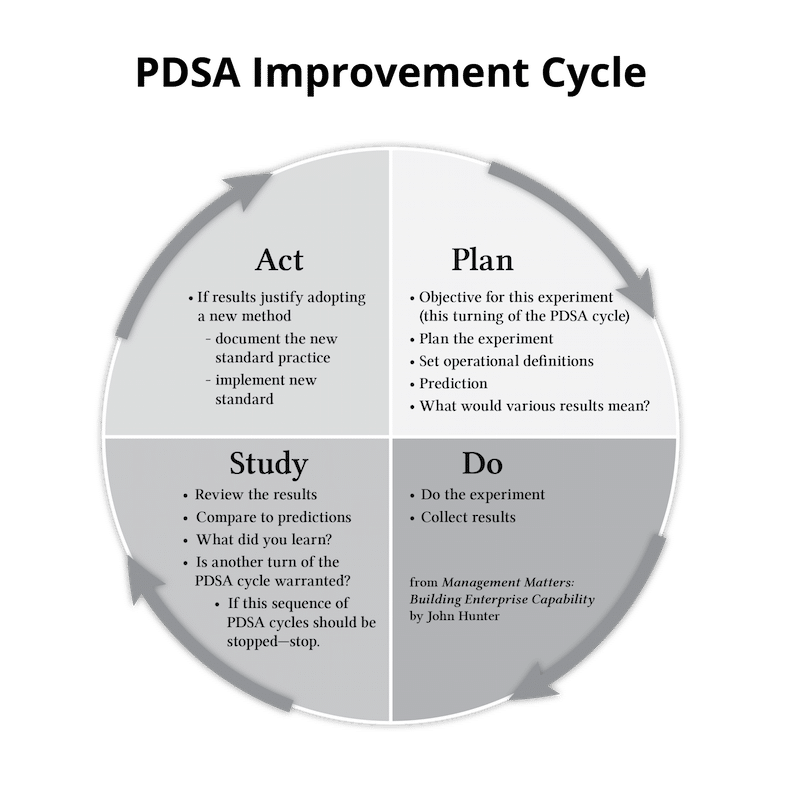

The Plan Do Study Act improvement cycle is a valuable method to maximize learning and catalyze improvement. See our Deming on Management: PDSA cycle resource page for many more details than are covered here.

Here I will just provide four ideas to keep in mind while using the PDSA cycle. In my experience, these ideas help people think more clearly about the PDSA cycle improvement process.

First, think of “Do” as “do the experiment.” Very often I see “do” as taken to mean “do the improvement.” That confuses the process in my experience. If it is clear that “Do” means “do the experiment,” it becomes much more obvious if there is no experiment being done (which is way more common than you might suppose). When “Do” is thought to mean “do the improvement,” it is possible to just apply some solution without any experiments.

Second, think of “Act” as either adjust, adopt, or abandon. Adjust is when you take what you learned from studying the results of the experiment and decide to adjust the experiment before running through the PDSA cycle again. Adopt is the decision to adopt the improvement. Abandon is when what is learned from the experiment just isn’t the right process to work on right now. Not only don’t you want to adopt this change, you don’t even see value in adjusting things to experiment some more.

When the decision is made to adopt the improvement, often it is wise to spend time figuring out the proper way to roll it out effectively. And it may well be wise to use the PDSA cycle process to experiment to find the best process to use to adopt the improvements. In very simple cases, it may be possible to just adopt the new improvements without much effort. (But often people make a mistake by not taking more time to make sure the improvements are adopted in a way that will be successful more widely.)

Third, “Study” is the step in which we study the results of the experiment. You can’t do that if you haven’t started the experiment (the PDSA experimental improvement) yet. But many people like to think of “study” as learning about the existing condition, which is a sensible thing to do before you design an experiment. But the “Plan” stage is meant to include the learning that is needed to design a sensible experiment.

I think we would all be better off just reinforcing that “Study” means “study the results of the experiment” and that “Plan” means learn about the existing conditions and create a plan for the experiment. What often happens is people talk about “studying” the existing conditions as being the necessary first step (which is true) but thinking that this is the study part of the PDSA, I think is wrong and leads to confusion.

Fourth, the PDSA cycle is meant to be cycled through quickly. The initial planning stage can take some time. But after that, the idea is to try a small experiment, learn from it, adjust a bit, do the new (adjusted) experiment, and then run through that process again and again and again. Often the planning stage in these subsequent cycles is very short, though occasionally, if the adjustments are more substantial, it may require more time to design a new plan for the experiment.

The Vanguard Method by John Seddon is focused on improving services. The method starts with the Purpose of the business and measuring the system from clients point of view. It applies a modified PDCA cycle. The method starts with Study/Check. Majority of businesses manage problems as work (?!). According to Phil Crosby up to 40% of what we call work is not only cost but failure to deliver on our Purpose. The Vanguard Method starts by cleaning the house. For example, practice some sampling by listening to phone calls over a week. (Do not be surprised if you find that “the fastest/best” workers hang off their phone if a client calls about a problem.) Another situation may be, say, to study medical findings (unnecessary or wrong requests for additional testing/medication) in order to reduce skills variation, problems, conflict of interest etc. By sorting out “failure demand” the front line staff will be more knowledgeable and effective in addressing the first wave of problems, the business will benefit from low costs, better service, engaged staff, higher customer satisfaction, etc. The method then focuses on the value demand, the Kano approach. Be proactive! What was a client’s reaction? It was OK, better than normal, or great! Any positive outlier?

Another approach is to start with identigying two extreme cases Pre-mortem (Total Failure) and Pro-Mortem (Huge success), then to fill the spectrum with different risks and achievements. During Study, we could practice AAR (After Action Report): What was right, What went wrong? What could we do better? And many other simple yet engaging techniques.

Also, during job interviews, delight job candidates by applying the same interview questions to your business: What is our strength? What is our weakness? What happened the last time we had a huge problem? Interesting, isn’t it?