By John Hunter, founder of CuriousCat.com.

From Out of the Crisis

The prevailing action during the crisis Dr. Deming alluded to in the title of his books was to cut costs to improve profits. Massive layoffs of employees would get executives big bonuses and send stock prices up. Sadly, focusing on cost cutting and layoffs is too often still the way some executives think.

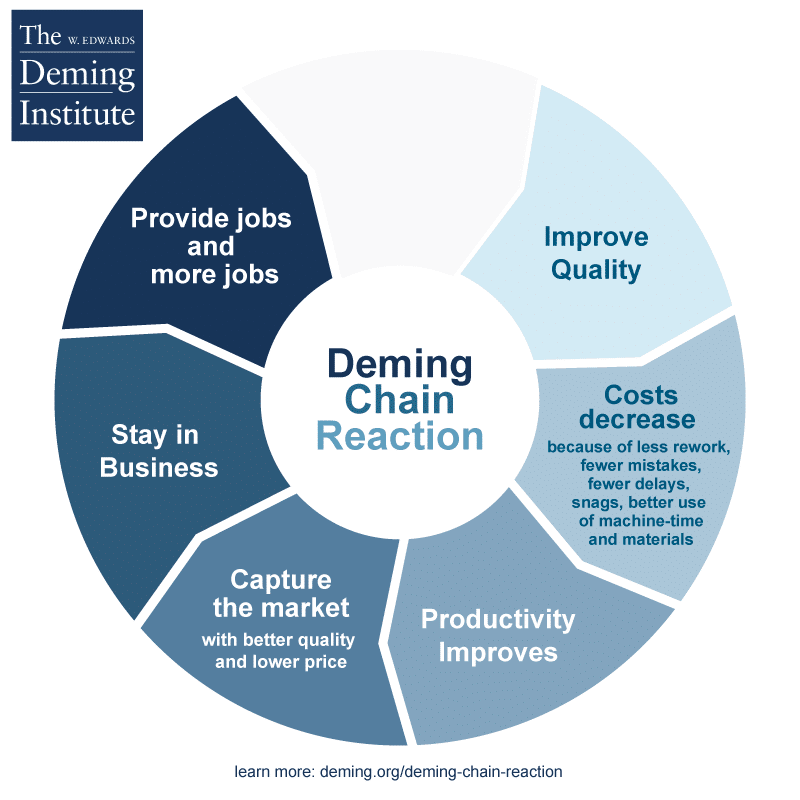

There has been more acceptance, though, of the idea that to improve, the focus should be on continual improvement, not cost cutting. By focusing on continual improvement you are able to remove waste, reduce errors, and remove delays. Reducing costs through process improvement, and at the same time improving productivity and product effectiveness, allows a company to benefit from the positive chain reaction Dr. Deming explained.

The chain reaction lets you reward workers as the company prospers, instead of seeking to prosper on the backs of workers. Flipping the means and the ends does not work. Reducing costs as the result of process improvement is effective management. Reducing costs based on a spreadsheet sent down by executives – and then hoping that the cuts don’t do too much damage to the value provided to the customer – is a recipe for disaster.

i want you to explain each of the deming steps from the beginning to the ending.

I’m TQN student and i want to deep understanding of it.

I want to understand more about Deming’s Chain reaction. I am a TQM student.

That’s great! We’ll reach out by email to see how we can help.