Guest post by John Hunter, author of Management Matters: Building Enterprise Capability.

Using data to access and guide improvement efforts is extremely useful. Data must be used appropriately, however. Thought must be given to understand the systems being studied and what the data actually indicates. It is easy to be misled if you are not careful.

Many supply chain problems caused by the economic impacts of COVID-19, and our responses to managing (or failing to manage) the public healthcare system problems, continue to impact the global economy. One of those supply chain problems is visible at the USA ports and specifically the Los Angeles, California ports (the Los Angeles and Long Beach ports).

The global supply chain system is very large and complex. What data you would want to look at to aid your understanding and provide indicators for whether conditions are improving or worsening (hopefully that are being used to access experiments – PDSA cycle improvements etc.) will depend on what you are trying to improve. Most of the time such efforts are likely to be very specific since usually you are not working on improving macroeconomic systems.

One nice thing about looking at macroeconomic-level systems is that viewing, at such a large scale, means all the small complexities that are parts of systems fade away when taking such a high-level view. Of course, this is also a big problem with looking at such high-level systems. Often there are so many influences on the end results that it is difficult to see connections between actions and results.

Recently, the transportation portion of the supply chain has come under scrutiny. The whole shipping system is running into problems. And the USA portion of the system is a big part of the global problem. There are many reasons for the problems (Analyzing the shipping backlog from one of America’s busiest ports is one of many examinations of some of the issues).

Attempts to focus and find the constraints within the system to work on can be useful. In huge complex systems, this isn’t nearly as easy as it seems, however. It isn’t hard to look at the USA and see backlogs being created by the ports.

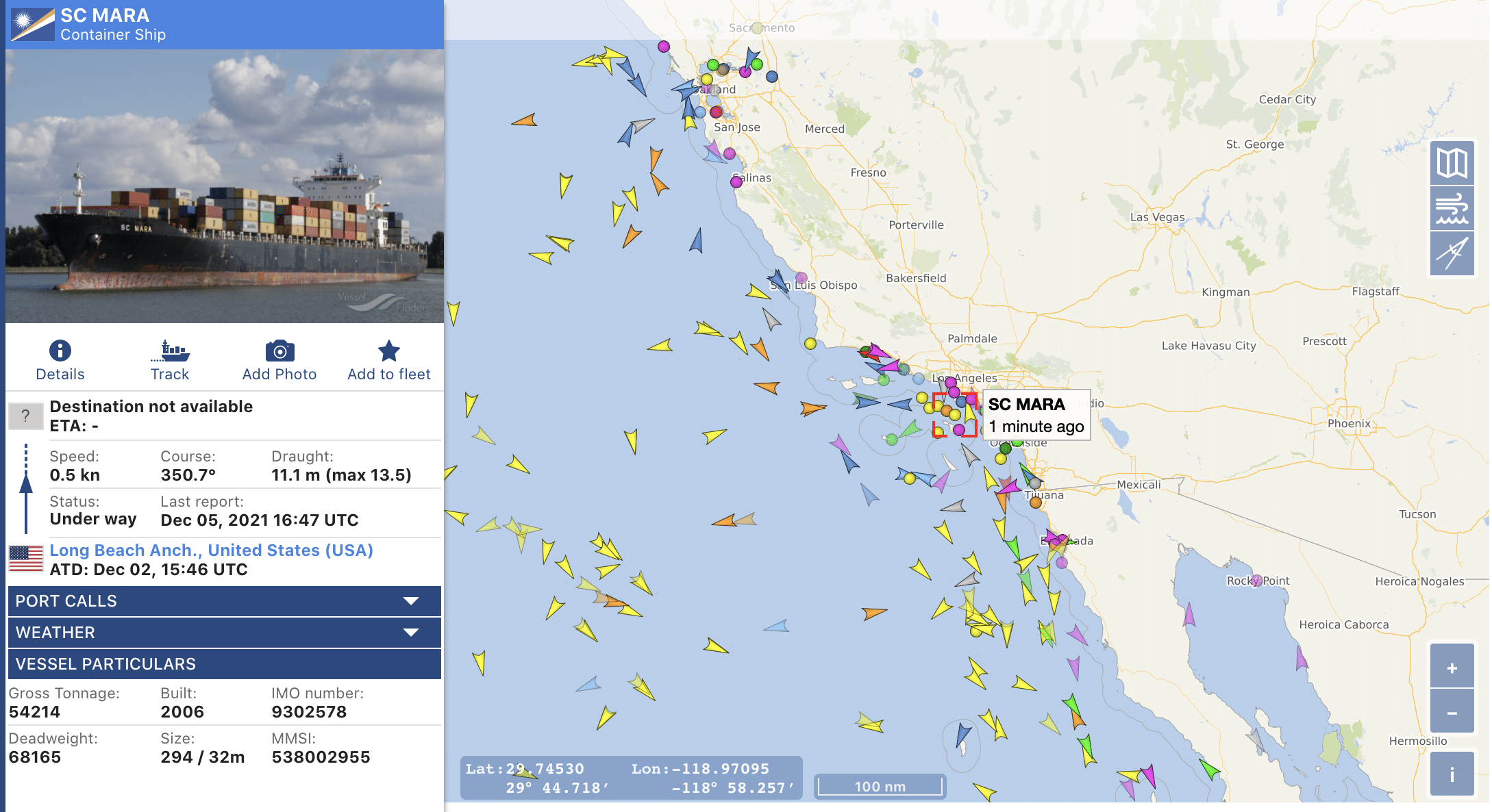

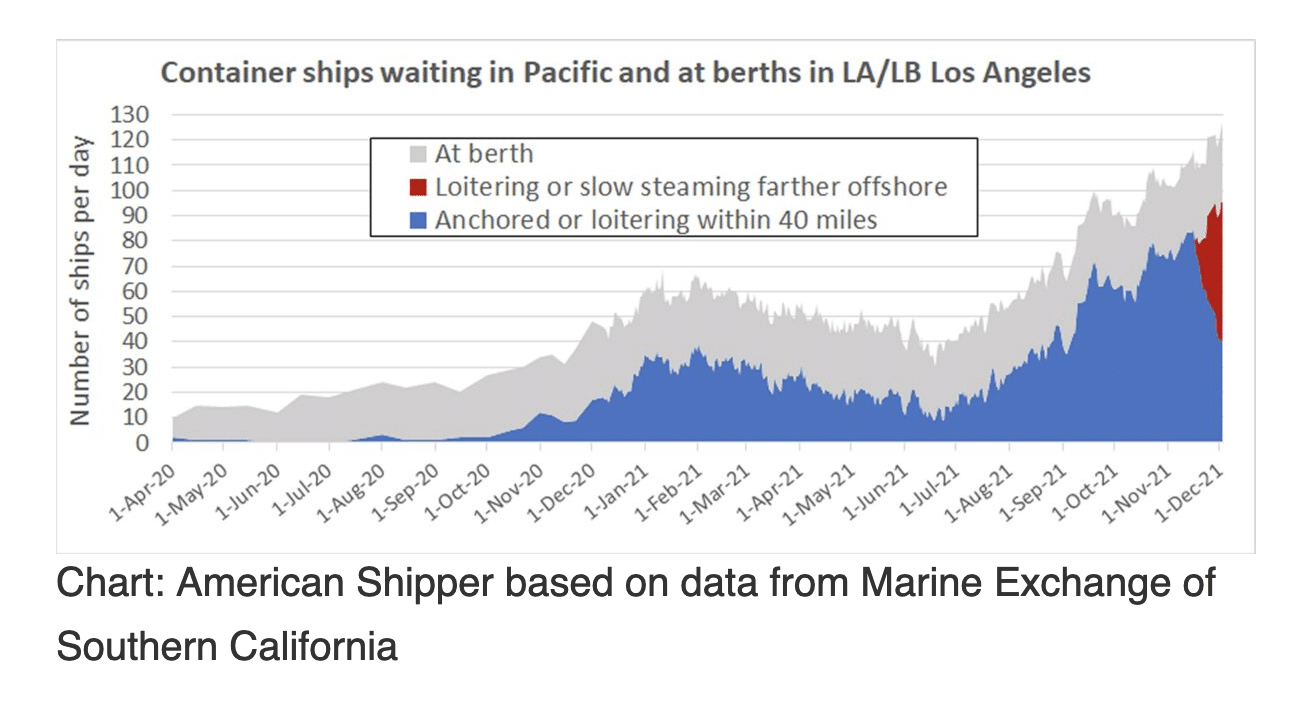

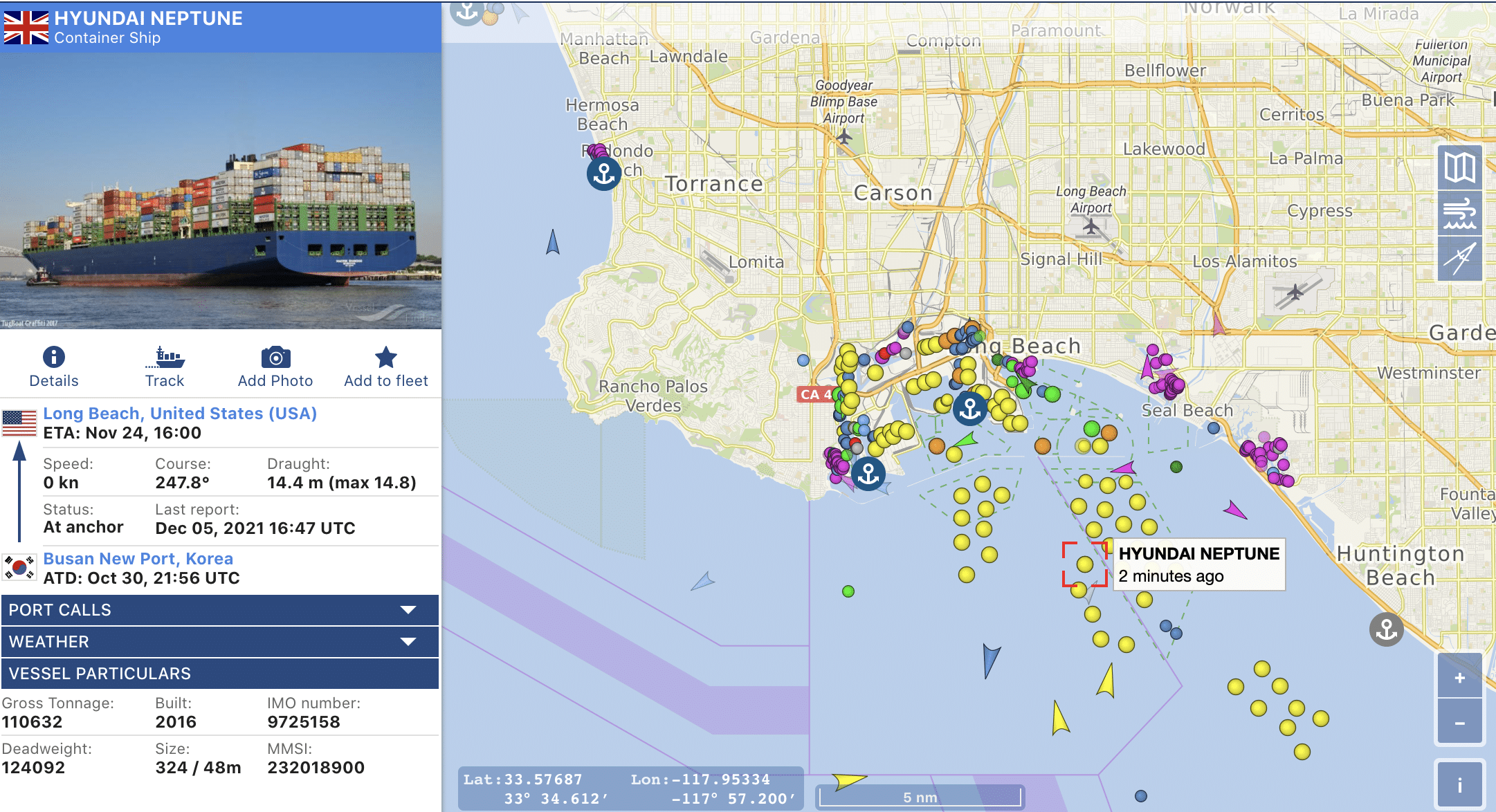

In 2021, there are increasing number of container ships waiting to get into the LA ports. And there is plenty of evidence of retail sellers in the USA that can’t get products from overseas to their warehouse and stores to sell. There are plenty of additional complexities around internal USA transportation constraints and other constraints (shortages of semiconductors…). Still the backlog of container ships is a visible issue, and one that seems focused enough to work on. And so, there has been an effort to do so.

Reducing the backlog of ships waiting to dock at the ports isn’t a direct solution. Just telling any waiting ship to go home doesn’t fix the problem. The problem is processing the ship’s cargo so that the cargo is moved through the system and is available to those wanting the cargo inside the USA somewhere. If you use the backlog of ships as a proxy for how you are doing the easiest way to improve that number, is just to distort the system (or just distort the figure directly). Recently there has been an effort to reduce the backlog of ships.

So, guess what has happened? The system has been adjusted to push ships out of the area counted for the “backlog” and thus improve the number. But this does nothing to improve the actual results that we want to see (It’s official: 96 container ships are waiting to dock at SoCal ports).

The ports are taking some measures to improve throughput at the ports. There are so many containers piled up at the port (due to various problems with the system) that it reduces the efficiency of the port. So, they are trying to improve that situation. And seem to be doing so, though it is not obvious that it is making a significant difference to throughput yet.

Reducing the reported backlog number by pushing the ships into waiting further out at sea does almost nothing. It certainly doesn’t improve the supply chain in any way. There is a bit of improvement in the local area, reducing pollution and sight lines for people living in the area.

So, it may be the right decision to push the ships to wait further out at sea, but claiming the backlog is improving when really the only change is that the reported number has been adjusted to look better is not helpful. Another change that was made lets a ship get in line based on the “expected time of arrival” instead of ships being taken in the order they arrive. This is an improvement when you have a big backlog as it allows the ships to burn less fuel at a lower speed, instead of going full speed just to wait for several weeks at anchor. It is a fairly minor benefit but still is a sensible improvement.

It is easy for your own organization to fall into such traps where the focus is on improving a number instead of improving they actual results. It is easy to start seeing the number as reality instead of as proxy. But understanding and appreciating that difference is critical to using data to continually improve.

October cargo volumes through the Port of Los Angeles fall year-over-year despite the long line up of ships waiting to offload “The Port of Los Angeles reported October 2021 volumes of 902,644 TEUs [twenty foot equivalent container units], a decrease of 8% compared from 2020 when it handled record monthly volumes.

Still, year-to-date overall cargo volume through the Port of Los Angeles, the top container port in the United States, has increased 22% over 2020.” It sure doesn’t seem like a good sign that the port is processing fewer containers while having such a huge backlog.

The USA ports have long been inefficient compared to the rest of the world. And while ports around the world have been greatly increasing their efficiency, the USA ports are falling further behind. That is the biggest issue that needs to be addressed, it seems to me. But that requires long-term thinking, and it has been failures for decades that have resulted in an inefficient system. And the current macroeconomic conditions exacerbate that long-term problem. Finding band-aids to cope with those long-term failures in the short term is necessary.

But the most important improvement is to fix the problems that resulted in such inefficient ports in the USA.

In a review of 351 container ports around the globe, Los Angeles was ranked 328, behind Tanzania’s Dar es Salaam and Alaska’s Dutch Harbor. The adjacent port of Long Beach came in even lower, at 333, behind Turkey’s Nemrut Bay and Kenya’s Mombasa, the groups said in their inaugural Container Port Performance Index published in May.

…

Ports in Asia, the Middle East and North Africa dominated the top 50 spots, while just four U.S. ports cracked the top 100 – Philadelphia (83), the Port of Virginia (85), New York & New Jersey (89) and Charleston, South Carolina (95).

When system-wide improvements mean that some who are getting rich off the current inefficiencies will not be able to continue to take as much as they have been blocking, then those improvements are too likely an outcome. And it is more difficult to get improvement put in place if misleading data is used.

Why Aren’t America’s Shipping Ports Automated?

Comparing the ports of Oakland and Rotterdam shows just how far American ports are lagging when it comes to automation.

At a build cost of over $535 million, the Rotterdam port is now considered the most advanced in the world, with all three major parts of the container moving process automated. In Rotterdam’s other terminals, almost every single transport vehicle and stacking crane are fully automated.

A key reason that Oakland and the United States lag in terms of automation is that upgrading to automated systems is extremely expensive…

A second reason for the delay in adopting modern automation is the effect on union jobs. Some have estimated that if the Port of Oakland were to implement a modern level of automation, 40-50% of the jobs would be eliminated.

Organizational impediments to improvement often block improvement efforts. Over the long term, the costs of those failures to improve often increase and expand beyond the organization. In this example, the entire supply chain in the USA is impacted by the inefficiency of the USA ports. Those inefficient ports are the result of decades of failure to improve relative ports around the world that have been improving dramatically. Of course, this is just one part of the supply chain transportation system that is having a dramatic impact today.

This discussion on problems with the USA trucking system provides insight into the problems and why seeing a “trucker shortage” as a primary issue is a critical mistake. It seems to me that a huge part of the problem is paying truckers for piece work (Dr. Deming talked about the problems with this), and the ways that doing so means the powerful players in the USA transportation system don’t have their economic incentives aligned to improve the system.

If those powerful players had to pay the costs of delays and waste of driver’s time, they would have more reason to put in the work to improve the system to remove that waste. But if they can shift those costs to small independent truckers, they don’t have an incentive to improve the system. And the small independent truckers don’t have the power to influence the system to reduce the waste that much more powerful organizations do have. In some cases, drivers are not paid on a piece rate so that the costs of waste (waiting in queues etc.) are more directly borne by those with more power. But it seems that too much of the system now is not aligning economic incentives to improve the systems in order to reduce waste in the USA transportation system.

When examining systems and data, it is critical to gain insight into the systems. As Deming said, expert knowledge is critical (“there is no substitute for knowledge”). It is also important to be careful of the dangers that come from familiarity with the historical conditions. It is easy to become blind to good options because familiar choices and actions are so comfortable. An understanding of systems thinking (to see the interactions and interdependencies), psychology (to understand how people can be mislead by data, others and even themselves) and an understanding of data and variation (to know what the data is and is not telling you about the system you are seeking to learn about) is critical to efforts to improve results.

The more experience you gain trying to improve, the better you become at improving. That journey is not easy, but it is very rewarding. I find keeping your sight on the long term is a great help. If you focus too much on the short term (which is very easy to do), it is easy to become so invested in achieving a short-term success that you seek to find numbers that let you claim victory. That is the death of efforts to improve. It is just so easy to find some numbers that can be used to declare victory no matter how badly things are really going. Instead, accept that there will be many short-term failures and short-term successes, but each of those are fairly minor data points on the long term journey to create an organization that continually improves day after day, week after week, month after month, and year after year.

Related: The Futility of a Numerical Goal – U.S. Seaports: At the Crossroads of the Global Economy (1996) – Port of Los Angeles Facts and Figures Card